Today’s electronic systems are smarter, denser, faster, and significantly more complex than ever before. Whether it’s automotive electronics, advanced industrial equipment, telecommunications systems, or next-generation consumer devices, every product depends heavily on the integrity of its design data. And two of the biggest unsung heroes in maintaining this integrity are automated library management and BOM scrubbing.

While these may sound like back-office engineering processes, they actually play a decisive role in ensuring that designs are manufacturable, reliable, compliant, and truly production-ready. Without them, even the most brilliant design can become vulnerable to errors, delays, and costly redesign cycles.

Why Component Libraries Matter More Than Many Teams Realize

Every design begins with components. These components live inside CAD libraries as schematic symbols, footprints, and associated parametric data. If a footprint is wrong or a pin mapping is incorrect, the PCB layout may assemble incorrectly or fail electrically. In a world where timelines are tight and products cannot afford failure, such mistakes are simply too expensive.

Automated library management eliminates these uncertainties. Instead of engineers repeatedly creating parts manually, automation enables organizations to:

- Maintain centralized, standardized component libraries

- Enforce IPC-compliant footprints

- Track part revisions with version control

- Ensure symbols, footprints, and attributes remain synchronized

The real advantage is consistency. With automation, every designer pulls from the same validated, trustworthy library. That improves collaboration, accelerates design cycles, and significantly reduces the risk of last-minute surprises. For teams working with external engineering partners or outsourcing a PCB design service, having reliable, well-managed libraries often becomes the foundation of predictable execution.

BOM Scrubbing: Turning a Parts List into a Manufacturing-Ready Asset

If libraries ensure “what you designed” is technically correct, BOM scrubbing ensures “what you plan to build” is practically feasible. The Bill of Materials isn’t just a list of components; it determines availability, cost, lifecycle stability, and compliance alignment.

BOM scrubbing automates the process of validating every component against real-world conditions. That includes checking:

- Component lifecycle status (Active, NRND, or End-of-Life)

- Supplier availability and lead times

- Regulatory compliance, like RoHS and REACH

- Alternatives or cross-reference parts if primary components are at risk

When BOM scrubbing is automated, issues are caught early rather than weeks later during procurement or manufacturing planning. For projects relying on a PCB solution ecosystem where multiple stakeholders collaborate, this degree of visibility is priceless.

The Powerful Link Between Libraries and BOM Integrity

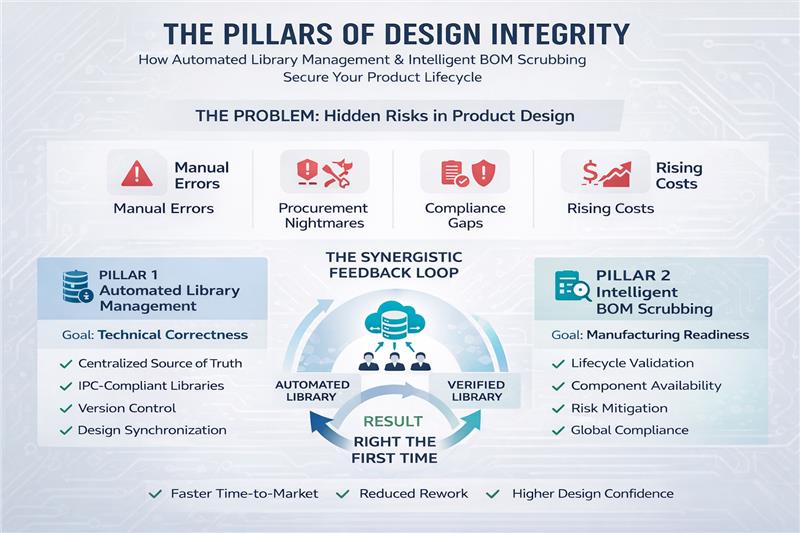

Library management and BOM scrubbing are most effective when they operate as an interconnected ecosystem rather than isolated tasks. Together, they create a data feedback loop that strengthens design quality at every stage:

- Verified libraries enable accurate BOM generation

- BOM intelligence feeds back insights like obsolescence and availability

- Automation ensures continuous synchronization between engineering and supply chain realities

This is particularly critical in industries dealing with demanding reliability standards, certification constraints, or high production volumes. It also ensures smoother downstream processes like fabrication, assembly, testing, and validation, whether handled internally or through a specialized partner offering PCB hardware design expertise.

To better understand how these two processes serve as the foundation of a successful build, let’s visualize the synergy between library precision and supply chain intelligence below. This ‘Data Feedback Loop’ is what separates high-reliability designs from those prone to costly delays.

This is particularly critical in industries dealing with demanding reliability standards, certification constraints, or high production volumes. It also ensures smoother downstream processes like fabrication, assembly, testing, and validation, whether handled internally or through a specialized partner offering PCB hardware design expertise.

To better understand how these two processes serve as the foundation of a successful build, let’s visualize the synergy between library precision and supply chain intelligence below. This ‘Data Feedback Loop’ is what separates high-reliability designs from those prone to costly delays.

As shown above, the transition from manual checks to an automated ‘Result: Right the First Time’ workflow isn’t just about convenience; it’s about risk mitigation. Without this synchronized loop, teams often fall into the trap of the ‘predictable set of problems’ discussed below.

What Happens When These Processes Aren’t Automated?

Teams that rely heavily on manual part creation and spreadsheet-based BOM checks often battle a predictable set of problems:

- Conflicting or outdated library versions

- Increased human error

- Misaligned footprints and symbol definitions

- Delayed discovery of obsolete or unavailable parts

- Repeated prototype spins and schedule overruns

As designs scale in layer count, speed, density, or mixed-signal complexity, the cost of these issues multiplies. That is why mature engineering organizations embrace automation not as an optional enhancement but as a strategic necessity. Automation also strengthens collaboration, especially when working alongside external engineering teams delivering PCB design service engagements or comprehensive system-level design programs.

Looking Ahead: A Future Driven by Intelligent Automation

The future of design integrity is moving toward deeper digitalization. AI-enabled component recommendations, real-time sourcing intelligence, cloud-based shared libraries, and automated compliance validation are already reshaping how teams work.

Instead of reactive corrections, engineering teams now operate with proactive confidence, identifying risks long before they affect schedules or hardware outcomes. Combined with modern engineering practices, this creates stronger design foundations and accelerates innovation while maintaining control. When integrated with advanced workflows like system-level validation or complete PCB solution delivery, automated integrity management becomes a genuine competitive advantage rather than just an engineering process.

Real-World Relevance in Complex Product Development

Think about industries like telecommunications infrastructure, automotive radar, aerospace electronics, or high-speed computing. These systems may involve extremely dense layouts, strict compliance mandates, and extended production lifecycles. In such cases, even a small unchecked library error or an overlooked BOM risk can become a multi-million-dollar issue.

With synchronized libraries, smarter documentation, and continuous BOM validation, engineering teams work with greater assurance and smoother execution. This confidence naturally extends into fabrication, assembly, testing, deployment, and long-term field reliability, exactly where strong PCB hardware design governance truly proves its worth.

Real-World Relevance in Complex Product Development

Think about industries like telecommunications infrastructure, automotive radar, aerospace electronics, or high-speed computing. These systems may involve extremely dense layouts, strict compliance mandates, and extended production lifecycles. In such cases, even a small unchecked library error or an overlooked BOM risk can become a multi-million-dollar issue.

With synchronized libraries, smarter documentation, and continuous BOM validation, engineering teams work with greater assurance and smoother execution. This confidence naturally extends into fabrication, assembly, testing, deployment, and long-term field reliability, exactly where strong PCB hardware design governance truly proves its worth.

High-Density Interconnect (HDI) PCB Design: Best Practices for Complex Products

Tessolve: Delivering Reliability, Precision, and End-to-End Engineering Excellence

At Tessolve, we take pride in enabling customers to succeed in complex product journeys with precision, discipline, and innovation-driven engineering. With our strong expertise across semiconductor engineering, embedded systems, validation, and advanced hardware development, we deliver dependable design execution that aligns with real-world manufacturing requirements. Our approach integrates robust automated library management, intelligent BOM validation, design optimization, high-speed layout capability, thermal and signal integrity assessment, and comprehensive test readiness, ensuring every project is built on trustworthy engineering data. When you partner with us, you benefit from global engineering experience, strong quality frameworks, and a commitment to delivering right-first-time outcomes for mission-critical products. Let’s build smarter, stronger, and future-ready electronics together.

Frequently Asked Questions

Why is automated library management important in electronics design?

It ensures standardized symbols, accurate footprints, and consistent component data, reducing design errors, rework, and costly manufacturing failures.

What does BOM scrubbing actually help prevent in real projects?

BOM scrubbing prevents the use of obsolete, unavailable, or non-compliant components, helping teams avoid delays, redesign efforts, and procurement risks.

How do automated workflows improve overall PCB development efficiency?

Automated workflows reduce manual effort, ensure data accuracy, improve collaboration, and accelerate design-to-production timelines with greater reliability.

Is BOM scrubbing only useful for large, complex designs?

No, even smaller designs benefit, as it improves component availability, lifecycle stability, and manufacturing readiness across every project scale.