The optimal device and application testing environment

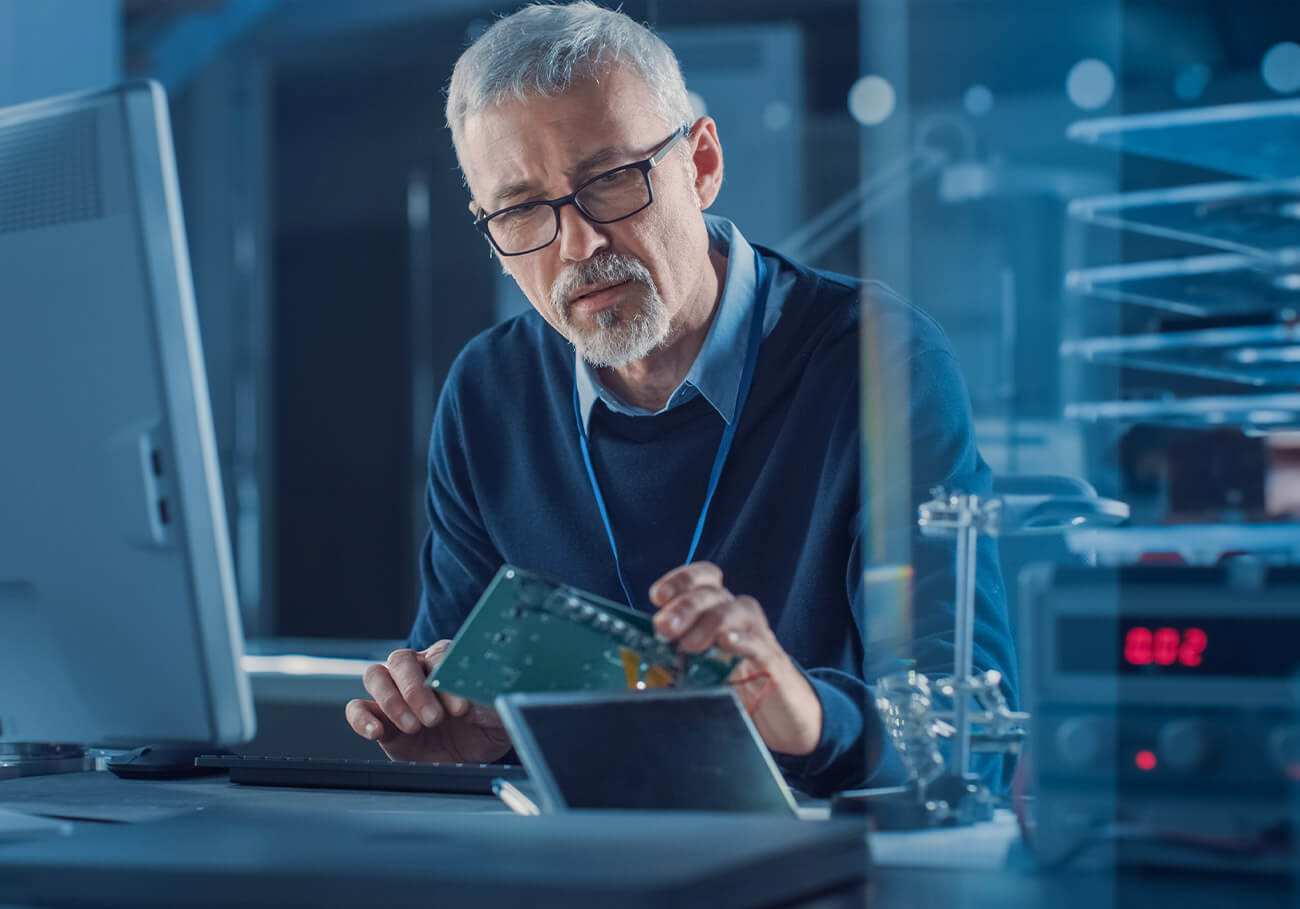

Bench Characterization Lab

Perfect test bench for chip test plan

From Post Silicon Electrical Validation to Characterization at Test Bench, assessing and validating modern Chip designs become a necessity for debugging operations during the device wake-up. The initial wake-up requires a bench setup for running simulations and mapping device behavior. The outcome is a more accurate specification in the product data sheet. Bench Characterization – an important step towards identifying the right board design through the optimal parasitic and accurate environment, provides the best test conditions ensuring correct measurement of data.

Our Test Bench Activities

Excellence in post-silicon validation & characterization

Our teams excel in rendering Test Services related to Post Silicon Electrical Validation and Characterization at Test Benches for top notch silicon manufacturers worldwide.

Latest In Our Facility

State-of-the-art tech for advanced testing