System-level testing is the final frontier where semiconductor devices and embedded systems prove their readiness for the real world. Unlike block-level or functional testing, system-level validation verifies how a device behaves under realistic operating conditions, including workload stresses, environmental factors, and hardware-software interactions. For industries like automotive, IoT, consumer electronics, and industrial automation, this stage ensures that end products perform reliably, safely, and efficiently.

This blog explores effective system-level testing techniques and why they are critical for ensuring product success.

Why System-Level Testing Matters

System-level testing goes beyond verifying functionality; it validates end-to-end product readiness. Its importance can be understood through the following points:

- Reliability: Ensures devices can withstand long-term operation and environmental challenges.

- Integration: Verifies seamless hardware-software interaction across subsystems.

- Performance: Confirms efficiency under typical and peak workloads.

- Safety: Identifies failure modes and validates recovery mechanisms.

- Compliance: Supports certification and regulatory approvals.

- Market readiness: Reduces field failures and accelerates time-to-market.

By addressing these factors, organizations minimize risk and deliver robust, customer-ready solutions that succeed in demanding real-world environments.

System Level Testing – The Differentiator

Key System-Level Testing Techniques

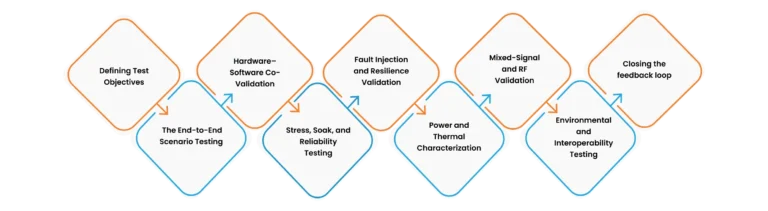

1. Defining Test Objectives

Every testing cycle must begin with clear objectives. At the system level, goals typically include:

- Functional correctness across all operating modes

- Performance validation under typical and extreme workloads

- Power and thermal behavior within design limits

- Failure mode analysis and fault recovery

Setting objectives early on offers a credible pathway for planning, coverage, and resource allocation. Usually, organizations rely on test engineering specialists to define meaningful test vectors and to outline acceptance criteria that closely resemble real-world use cases.

-

The End-to-End Scenario Testing

System-level testing should also simulate real-life scenarios. For embedded systems, this means booting the system, updating firmware, and recovering from errors. Workloads for semiconductor devices run alongside board-level integrations, with the goal of identifying bottlenecks or hidden failures.

Here is the critical function performed by semiconductor test engineers. They take multifaceted user journeys, transform these into reproducible test cases, ensuring every function, from I/Os to data integrity checks, is tested satisfactorily.

3. Hardware–Software Co-Validation

Most modern failures occur not in isolated hardware or software, but in their interaction. Co-validation ensures firmware, drivers, and hardware logic work seamlessly. Early iterations may use emulation, but final validation requires silicon-in-the-loop environments where timing and analog effects come into play.

This is an area where test engineering teams bridge design and software groups, reducing integration errors and catching regressions quickly with automated test harnesses.

4. Stress, Soak, and Reliability Testing

Reliability testing goes beyond functionality. Stress tests push devices beyond nominal limits, while soak tests expose them to extended runtime workloads. These methods uncover early wear-out mechanisms and potential design weaknesses.

An experienced semiconductor test engineer typically defines stress thresholds, monitors degradation, and collaborates with design teams to suggest improvements. By combining stress data with reliability modeling, organizations minimize costly field failures.

5. Fault Injection and Resilience Validation

The failure of a system brings about certain phenomena. Fault injection, the conscious induction of errors, e.g., voltage drops, communication timeouts, and corrupted data, assists in validating that the system in question reacts accordingly. This gives one confidence in the proper functioning of watchdogs, error handlers, and safety precautions. Engaging professional engineering testing services ensures fault injection is done with sufficient depth to extract the pertinent information onto recovery paths and safe-state transitions.

6. Power and Thermal Characterization

System-level testing must verify real-world power behavior across all states, including active, idle, and sleep. Power-domain transitions, current leakage, and efficiency of dynamic power management are analyzed. Thermal testing enhances cooling solution certification and hotspot distribution under load.

Test engineering teams contribute valuable expertise on measurement accuracy and provide actionable feedback for design improvements.

7. Mixed-Signal and RF Validation

Embedded systems increasingly integrate analog and RF components. Testing at this level requires evaluating spectral purity, sensitivity, interference resistance, and wireless coexistence. Issues like digital noise coupling into analog paths often only appear in system-level contexts.

A semiconductor test engineer with mixed-signal expertise is essential to design validation protocols that reveal subtle analog-domain interactions.

8. Environmental and Interoperability Testing

Beyond functional testing, products should be durable enough to withstand environmental abuse from temperature, humidity, and vibration. Interoperability testing helps validate that products behave as intended across networks, protocols, and ecosystems. Interoperability is paramount for IoT and automotive.

In the end, utilizing an engineering testing services provider will enable you to take advantage of the remaining suite of chambers, interoperability labs, and compliance test suites designed for improved system stability.

9. Closing the feedback loop

The system-level performance information will be returned to design processes to aid in further improving testability, and more specifically, in developing better reliability statistics. This is the requisite feedback loop that allows an organization to iterate on the product and its test methods.

Altogether, investing in test engineering knowledge should reduce the gap that separates assessment from design intention, shorten development cycles, and increase the overall quality of the product.

The Future of Test Engineering: How Automation is Changing the Game

Tessolve: Driving Innovation in System-Level Testing

System-level validation means much more than a process; it is truly a matter of concern to us at Tessolve. A well-designed ASIC represents the heart of a reliable product, and the expert teams of semiconductor test engineers develop custom test programs to suit each customer’s needs. This improves yield, reduces debug time, eases compliance, and reduces overall costs.

With strong infrastructure and state-of-the-art laboratories, we offer a comprehensive suite of engineering test services: post-silicon validation, production testing, and reliability evaluation. Tessolve gives the confidence to semiconductor and embedded companies worldwide to deliver their products faster, stronger, and with future-proof design. When you choose Tessolve, you choose more than a vendor; you have a genuine partner who has a vested interest in your success.