In the highly competitive field of semiconductor fabrication, the efficiency of operations and minimal equipment downtime are crucial ingredients to success. Incorporating Artificial Intelligence (AI) and Machine Learning (ML) in predictive maintenance schemes could be a game-changer in accomplishing these goals. This article delves into how AI and ML transform predictive maintenance within semiconductor fabrication and the potential overlap with semiconductor engineering, design services, and specialized semiconductor solution providers..

What is Predictive Maintenance in Semiconductor Fabrication?

Predictive maintenance is the anticipation of equipment failures before they occur, hence providing enough opportunities for intervention to minimize unexpected downtime and expensive repairs. Preventing equipment failure in semiconductor fabrication, where precision and continuity in operation are of the utmost importance, is predictive maintenance, as it ensures product quality and yield.

The Role of AI and ML in Predictive Maintenance

Advanced technology of AI and Machine Learning is leveraged to analyze voluminous data being generated by fabrication tools to discover patterns and anomalies, usually indicative of impending failures. Chip design companies and semiconductor service providers can leverage this data for timely and cost-efficient maintenance strategies.

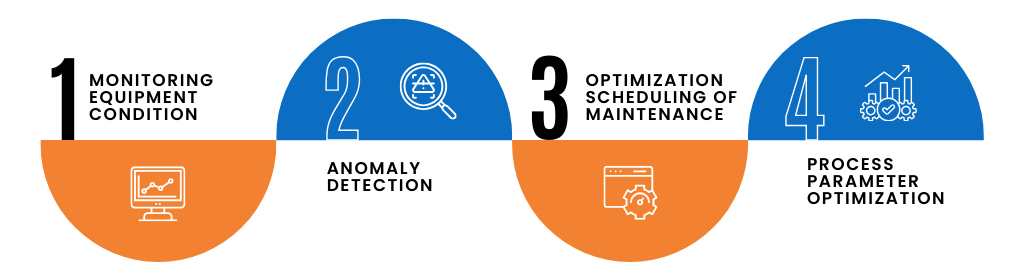

- Monitoring Equipment Condition: By analyzing sensor data, machine learning algorithms evaluate machine health on a real-time basis. Machine learning prediction of the time-to-failure for plasma etch equipment could reduce unscheduled breakdowns, delivering cost savings with enhanced production output.

- Anomaly Detection: AI takes the deviations from the normal or proper operating condition and immediately alerts the service personnel of any condition that may develop into equipment failure. Therefore, semiconductor service companies could address the problem before it gets magnified.

- Optimization Scheduling of Maintenance: Prolific AI will foresee impending problems with the equipment and thus will contribute to scheduling maintenance work during off-major production slots, thereby reducing disruption of production while yielding optimum use of resources.

- Process Parameter Optimization: Machine learning models analyze process parameters to determine the optimum parameter settings that will reduce the wear and tear on the machine and thereby extend its lifespan while improving overall efficiency.

Benefits of Implementing AI/ML in Predictive Maintenance

- Reduced Downtime: Predictive maintenance seeks to identify potential points of equipment failure and offers remedies on time, thus assuring a steady supply of output in meeting delivery schedules.

- Cost savings: Proactive maintenance is aimed at reducing repair costs and prolonging the life of the equipment, which will ultimately lower costs for companies relying on semiconductor design and engineering services..

- Enhancing Product Quality: Keeping the equipment in harmony with its initial specifications will yield an acceptable and predictable experience through the product cycle, which is paramount in semiconductor manufacturing.

- Improved Safety: Timely detection of any problems with equipment can significantly reduce the likelihood of accidents, therefore providing a safer working environment.

- Making the Right Decision in Real Time: AI-based solutions for predictive status monitoring will make it possible to make quick decisions that can be made in real-time through the timely capture and analysis of data. This entails quick action taking when the need arises, thereby limiting extended downtime and production halts.

- Data-Driven Insights for Improving Processes: Predictive maintenance not only averts failures but also provides insights that can be mined and applied for improving semiconductor fabrication processes. It enhances identification of inefficiencies, smoothens operations, and raises productivity in overall manufacturing.

Challenges and Considerations

While benefits abound, there are challenges in the application of AI/ML predictive maintenance.

- Data Quality and Integration: High-quality and well-integrated data from diverse sources is essential to ensure accurate and reliable predictive analytics.

- Recruitment of Highly Specialized Experts: AI and machine learning require specialized expertise, making it challenging to address skill gaps through targeted training or strategic hiring.

- Upfront Costs: Deployment of AI/ML technologies involves significant expenditure, hence may deter adoption from some organizations.

- Scalability: To address compatibility and scalability issues across multiple semiconductor facilities, companies must develop comprehensive implementation strategies tailored to varying operational scales..

Tessolve’s Contribution to AI-Driven Predictive Maintenance

Tessolve, an established semiconductor service provider, is delving deep into the future of predictive maintenance solutions through the integration of AI and ML. Their Edge AI Integrator converts connected products into intelligent systems and enables predictive maintenance for Industry 4.0 applications. This solution caters to diverse industries, including automotive and industrial markets, by providing advanced hardware and software capabilities for end-to-end IoT business solutions.

Tessolve’s semiconductor engineering capabilities help manufacturers improve reliability and efficiency by applying AI-based analytics. With complete semiconductor design and validation services, Tessolve allows businesses to apply robust predictive maintenance strategies against specific fabrication processes. Companies gaining from collaboration with Tessolve obtain end-to-end solutions that tackle moderation in production quality, combine process stability, and maintain equipment longevity.

Exploiting the AI competency of Tessolve will allow semiconductor firms, especially those focused on design and fabrication—to elevate their maintenance strategies, minimize downtime, and improve overall operational efficiency. The research-and-development department of Tessolve in semiconductor engineering assures that clients stay ahead of the game in this fast-evolving industry.

The Future of Predictive Maintenance in Semiconductor Fabrication

AI and ML brought into predictive maintenance will become mainstream in semiconductor fabrication. As these technologies mature, they will deliver smarter and more sophisticated tools in semiconductor engineering to allow precise predictions and efficient maintenance strategies.

AI/ML-driven predictive maintenance has become imperative for semiconductor design companies and semiconductor service providers to stay ahead in this highly competitive market.

The Future of Semiconductor Design: How Emerging Technologies Are Shaping the Industry

Let’s Conclude

Leveraging predictive maintenance through AI and ML in semiconductor fabrication is a great leap forward in semiconductor engineering. Semiconductor companies—spanning design, services, and engineering—adopting AI-based predictive analysis now reap more productivity savings, products that deliver superior quality, and future potential to capture a competitive foothold through these novel technologies.

As the semiconductor industry continues to innovate, integrating AI and ML into maintenance strategies will play a pivotal role in shaping its future, ensuring that fabrication processes are efficient, resilient, and adaptable to emerging challenges.